AI-Powered Safety & Human Performance Monitoring

Next-Generation Safety Intelligence for High-Risk Environments

The Paradigm Shift from Reactive to Predictive Safety

In high-risk drilling and energy environments, human factors—including fatigue, distraction, and procedural deviation—are responsible for over 80% of operational incidents and near-misses. Traditional safety systems are inherently reactive.

We integrate proprietary advanced computer vision models, deep learning for cognitive fatigue detection, and sophisticated behavioral analytics to continuously assess crew situational awareness, physical state, and compliance.

The system immediately notifies rig supervisors and control centers with actionable alerts, ensuring risks are mitigated before they become costly, dangerous incidents.

Core Capabilities: Granular Intelligence for Unmatched Safety

Advanced Human Behavioral Safety & Compliance

Our proprietary Vision AI models are trained on millions of hours of operational data to observe, interpret, and score human behavior in real-time.

Unsafe Act Detection:

- Identifies immediate risks such as hand-in-pocket violations.

- Detects improper tool handling, dropped object potential, and unsecured movement in red zones.

Procedural Compliance:

- Tracks adherence to critical safety protocols (e.g., Lockout/Tagout verification, working at height procedures, use of personal protective equipment (PPE)).

- Analyzes worker, equipment, and workspace interaction to detect complex scenarios.

Output: Provides supervisors with aggregated Behavioral KPIs and targeted, evidence-based coaching insights.

Proactive Cognitive & Physical Fatigue Detection

Fatigue is a silent killer on the rig. Our system identifies the subtle, cumulative signs of mental and physical exhaustion.

Real-Time Biometric Proxies:

- Continuous monitoring of micro-movements, eye-gaze patterns, and head posture.

- Tracks sustained attention levels.

Predictive Intervention:

- Algorithms assess signs of reduced focus, mental deceleration, or increased stress that precede performance degradation.

- Platform forecasts fatigue trends based on shift patterns.

Recommendation: Suggests mandatory rest periods or re-tasking hours before performance is critically compromised.

Instantaneous Multi-Channel Risk Alerting (The 3-Tier Response)

When the real-time risk score exceeds a configurable threshold, the system initiates a coordinated, multi-channel response.

The 3-Tier Response:

- Tier 1 (Immediate): Automated voice announcements are triggered on the rig floor via integrated PA systems to draw immediate attention to the hazard.

- Tier 2 (Control Center):Real-time visual and audible alerts populate centralized control-center dashboards, providing instant geographical location and video evidence of the risk.

- Tier 3 (Supervisory): HSE Managers and Rig Supervisors receive push notifications via mobile or integrated fleet management systems, detailing the risk, its severity, and recommended immediate action.

Operational & Efficiency Optimization Analytics

Safety and efficiency are intrinsically linked. Our platform provides deep visibility into workflow bottlenecks and workforce utilization.

Key Optimization Insights:

- Task Cycle Time Analysis: Automatically tracks the time taken for key activities (e.g., tripping pipe, well head/ BOP installation) to identify delays and procedural friction.

- Workforce Utilization & Density Mapping: Visualizes crew movement and clustering to optimize staffing levels and minimize non-productive time (NPT).

- Data-Backed KPI Reporting: Generates auditable reports on Leading Indicators for continuous improvement and benchmarking.

Predictive Accident Prevention

By analyzing historical patterns and real-time behavioral and physical data, the system forecasts potential incidents before they occur.

Predictive prevention is the ultimate goal. The system generates an instant Dynamic Risk Score for every worker and every critical zone. It flags anomalies before they escalate, providing supervisors the necessary lead time to intervene and prevent incidents, moving safety governance into the preventative realm.

1. Behavioral Safety & Compliance

- Identifies immediate risks (hand-in-pocket, improper tool handling).

- Tracks adherence to safety protocols (e.g., PPE, Lockout/Tagout).

- Analyzes worker/equipment interaction in high-risk scenarios.

2. Proactive Cognitive Fatigue Detection

- Monitors micro-movements, eye-gaze, and attention levels (Biometric Proxies).

- Algorithms assess reduced focus and mental deceleration.

- Forecasts fatigue trends to recommend mandatory rest periods.

3. Instantaneous Multi-Channel Risk Alerting

- Tier 1: Automated PA voice announcements on the rig floor.

- Tier 2: Real-time alerts on centralized control room dashboards.

- Tier 3: Targeted push notifications to HSE Managers with recommended action.

4. Operational & Efficiency Optimization

- Task Cycle Time Analysis: Automatically tracks the time taken for key activities (e.g., tripping pipe, well head/ BOP installation) to identify delays and procedural friction.

- Workforce Utilization Mapping minimizes Non-Productive Time (NPT).

- Generates auditable KPI reports on Leading Indicators.

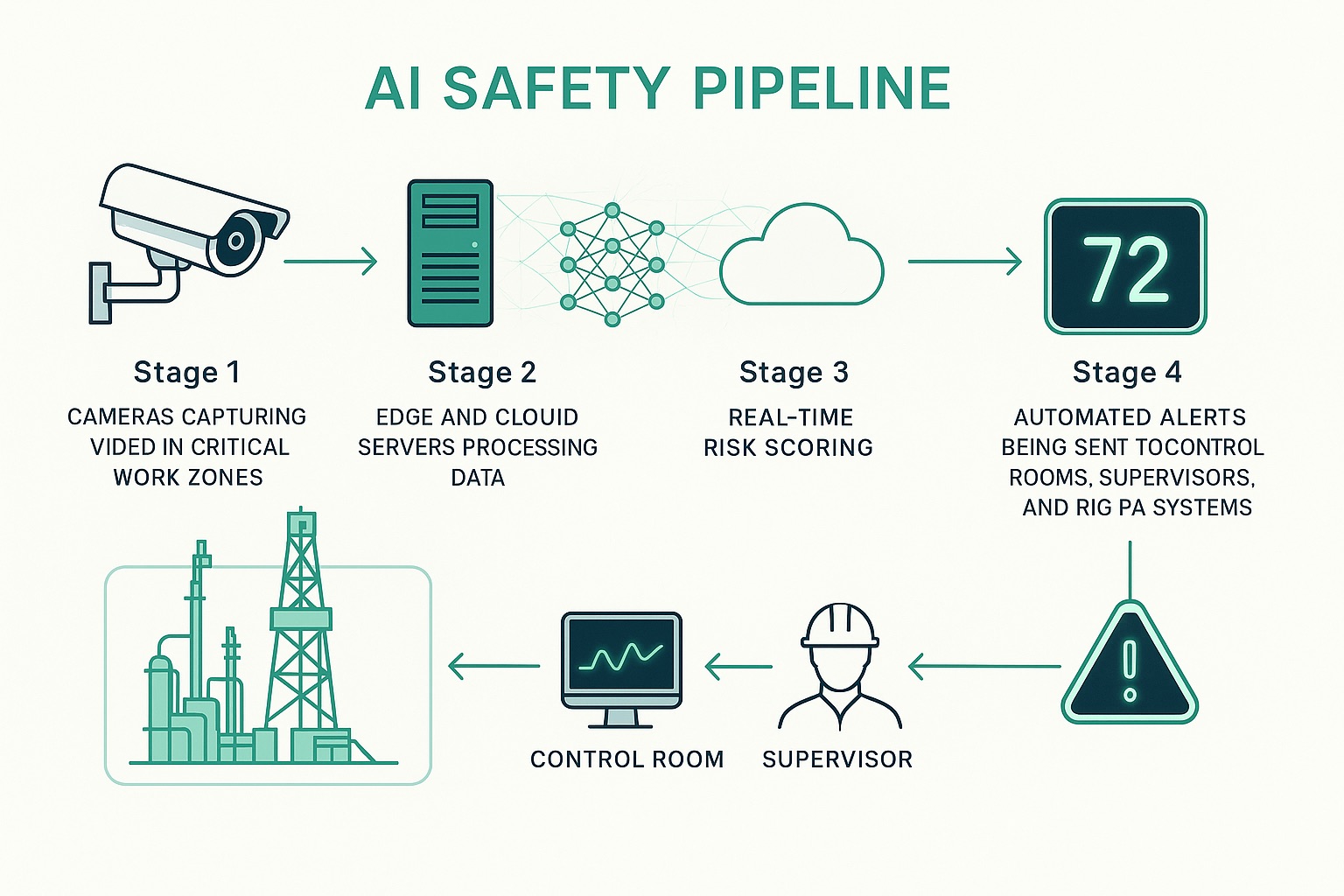

How It Works: The Vision AI Pipeline

The 4-Step Safety Flow

1. Data Capture & Aggregation: Cameras capture high-definition, anonymized video and sensor data from critical work zones.

2. Edge & Cloud Processing: Deep learning models run on edge-computing hardware for low latency, analyzing data against thousands of safety criteria.

3. Real-Time Risk Scoring: Anomaly detection algorithms instantly generate a dynamic risk score for every worker and critical zone.

4. Automated Governance & Feedback: High-risk scores trigger the 3-Tier Alert System, and daily reports guide coaching opportunities.

Summary: This end-to-end process transforms raw visual data into actionable safety intelligence in under a second, ensuring proactive incident prevention rather than reactive reporting.

Why It Matters: Quantifiable Value & ROI

Accident Reduction Goal

TRIR Reduction

Proactive intervention eliminates the leading cause of incidents: human error.

Uptime Metric

Minimize NPT

Real-time alerts prevent near-misses and equipment damage, decreasing Non-Productive Time (NPT).

Auditability

Video-Verified Audit Trail

Provides an objective, video-verified audit trail for every safety procedure and intervention.

This platform is not merely monitoring; it is intelligent, auditable, and preventative risk governance.

Ready to transform your installation’s safety?

Contact us to schedule a demo and gain intelligent prevention for your critical operations.

Contact Us for Deployment Plan